Polyamide Thermal Break Strip (PA66 GF25%)

Nurlu uses different materials such as PA66 GF25%, ASA, ABS, PVC. Being so, polyamide material is the most popular material for thermal break. Thermal insulating profiles made of polyamide PA 66 GF25% (25% glass fiber reinforced polyamide) have significant advantages.

The coefficient of linear thermal expansio (linear elongation coefficient) of the polyamide profiles is equivalent to the aluminum profile. Therefore, the polyamide profile is not subjected to internal stresses after it is pressed to aluminum profile. This is one of the most important advantages of using the polyamide material as a thermal barrier.

Secondly, the deflection temperature of the polyamide profiles under load is high. Even at 200° C for about 15 minutes, no deformation occurs. Therefore, it can easily be heated in the ovens at the powder coating process.

Thirdly, polyamide profiles do not emit toxic gases in case of fire. They are environmentally friendly.

In addition, dimensional stability and resistance to chemicals of polyamide thermal barriers are high.

Transport and storage recommendations for insulating bars

Polyamide thermal breaks are extruded in dry state but they absorb moisture from the environment after the production as time passes. Moisture level depend the following conditions;

- Ambient temperature

- Ambient humidity

- Storage period

Polyamide profiles should be transported and stored under dry conditions away from the influence of weather. (rain, direct sunlight etc.)

During the summer time, when the temperature and humidity in storage area are higher than usual, the insulating profiles absorb more moisture than in the remaining seasons, even stored properly.

Protecting against moisture will reduce any possibility of blister formation during powder coating.

Maintain ambient temperature in the range from 15 to 20 °C

Store profiles horizontally in order to prevent bending or twisting the material, otherwise long storage periods cause permanent sagging. Support long lengths.

Natural moisture absorption causes a slight dimensional increase and change in mechanical properties depending on the storage duration and ambient climate.

Thermal break assembly for aluminium profiles

Thermal break assembly in aluminum profiles takes place in 4 stages.

1- Knurling

2- Insertion of thermal barriers into aluminium cavities

3- Curling (Rolling, crimping)

4- Shear strength test

Knurling matters

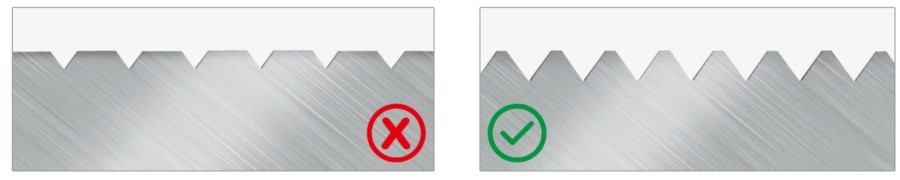

Aluminum profiles have cavities where thermal break strips are inserted. Knurling on the neck of this cavities is performed with the aim of increasing the shear strength. If the knurling process is not performed with sufficient care, the thermal break strips are not sufficiently connected to the aluminum profile cavities and the composite profiles cannot reach the desired values in the shear stress test. Knurling machines work on the principle of carrying out 2 hardened special discs on aluminum profile. In a suitable knurling process, sharp teeth must be formed on the aluminum profiles. This ensures sufficient adhesion between the plastic insulating bars and the aluminum profiles.

Discs used for knurling should be periodically replaced. Before the process, ensure that the discs are correctly aligned vertically and horizontally with the aluminum housing.

The image on the left shows an example of insufficient knurling. On the right, sharp-toothed aluminum is an example of good knurling we recommend. Good knurling is very important in terms of shear strength. Remember: Increasing the clamping pressure does not compensate for poor knurling.

Insertion and rolling of thermal break strips

It is possible to apply and tighten the thermal insulation barriers to the duct in aluminum profiles thanks to advanced machines. For a good compaction, the most suitable settings for the dimensions of the profiles are made automatically or manually on the machine. During the compaction process, the print settings should be carefully adjusted in order to avoid twists and breaks. Problems such as rotation, breakage or poor jamming are often caused by pressure from discs that are not correctly adjusted to the profile.

Shear strength test

Adhesion of heat barriers to aluminum profiles is measured by shear test. The EN 14024 standard specifies the requirements. Different factors contribute to the formation of a composite aluminum profile (combined with a thermal insulation barrier) with a high shear resistance. A good knurling is the most important one. In some polyamide thermal barriers there is a wire on the foot . This wire has no significant contribution to shear strength. Likewise, it is not possible to increase the shear strength by further pressing on the rolling process if there is not adequate knurling. The most important factor is a good knurling for a sufficient shear strength.

Coating of thermal breaks and resistance to heat

One of the most important features of polyamide thermal barriers is that it can be subjected to the heating, which is the final stage of electrostatic powder coating process. Composite (thermal barrier inserted) profiles shall be heated at a temperature of 180° C - 200° C not exceeding 20 minutes. If this limit is exceeded, the stability of the profiles is not guaranteed. Again, if this time is exceeded, the possibility of bubble appearing on the thermal barriers increases. In addition, profiles should be supported in the middle in horizontal production lines in order to prevent sagging.

Improving thermal insulation of aluminium windows and facades

Companies that develop aluminum windows and façade systems choose different thermal insulation barriers or design a custom profile for them in order to provide better thermal insulation systems considering the principles of thermal insulation. In order to understand these principles, we need to know the ways in which heat is transfered.

The transfer of heat from one substance to another takes place in three different ways: conduction, radiation and convection.

Conductive materials conduct heat directly from one side to another, that is called a thermal bridge as it is in our case with aluminium profiles. Heat is conducted btw inner and outer sides of the window or facade. The main task of using thermal break strips is to prevent direct transmission of heat through metal profiles. In this respect, insulated aluminum profiles are used in every application where thermal insulation is required. For the same reason, we prefer 24mm or 34mm heights for thermal breaks instead of 14.8mm, to minimize the transfer of heat through conduction. If the plastic profile is thin and long, the heat passes to the other side more difficult.

In a well-designed aluminum window and facade system, the thermal gap should be wider with respect to the direction of heat transfer. This is accomplished with thermal barrier profiles with higher profile heights. The longer the thermal insulation barrier, the greater the insulation gap and the better the insulation.

The transfer of heat by convection means the transfer of heat within liquids and gases. This is an important point in aluminum system design. We said that thermal cavities were created with thermal insulation barriers. When this gap is too large, it will be easier for the air to circulate inside and carry the heat. Therefore, when long thermal insulation barrier profiles are used, flags are used on the profiles in order to divide the gap into sections. When the insulation gap exceeds 24mm, thermal flags are added to the thermal insulation barrier profiles to prevent the transfer of heat by convection. Likewise, partitioning of the gaps in our chamber (hollow) insulating bars minimizes the transfer of heat through convection.

Some of our products:

14.8mm polyamide thermal break strips

Türkçe

Türkçe

English

English

русский

русский

Deutsch

Deutsch

العربية

العربية